SERVICE

Part analyze and feasibility study

Dema checks the part feasibility, inform and advice the customer concerning what to change and improve in order to achieve the requested quality and a safe production.

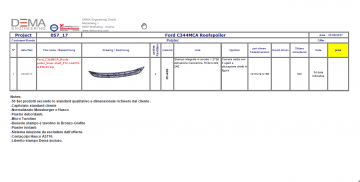

Quotation

When received an inquiry and after thecnical check Dema prepares an offer based on the customer requirments.

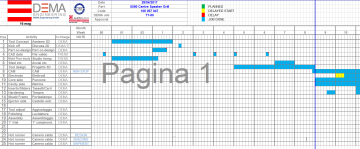

Activities and management plan

Dema manages and organizes all the activities from design to manufacture, checking the progress and informing the customer weekly by time schedule and pictures.

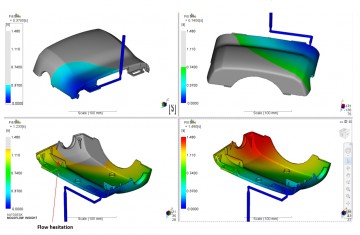

Mold flow

When requested and/or necessary Dema makes a mold flow study to choose the best feed system ,keeping the requested shape tolerance. Further meeting with customer to discuss and get approval for the proposed choice.

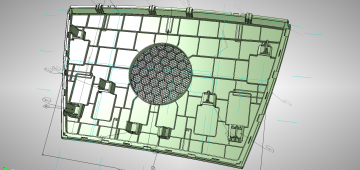

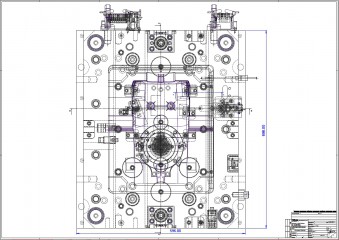

Making of tool GA and discussion

Based on customer requirments and press size, Dema prepares the General Assembly where to see the main features and discuss the details up till the final customer approval.

Tools design

Dema uses qualified and reliable design.

Tools manufacture

Dema works togheter with reliable tool shops in order to supply an high quality product.

Try-out and further improvements

Dema chooses the press suitable for the requested production and tool size, makes a detailed try-out report and defines further improvements necessary to achieve the requested quality of tool and plastic parts.

Pre-series production

Nowdays with always tight time it is often necessary produce small pre-series for several test like painting, assembly, measurements, etc.

Dema supplies the pre-series in the requested time with the use of several carriers for small and large shipments.

Turnkey service

Dema delivers the tool ready for mounting on production press.

In case of need Dema provides technical support and qualified persons in site for special demands.